11 April 2022

Sofa catalogue: in-depth study of the Abaco model

Focus on the ABACO model

Although we are convinced that beautiful and well-made things can be seen at first sight, we want to show you the Abaco model in detail, in an easy, clear and without incomprehensible terms.

The topics that we will discuss later, have the sole purpose of sharing our experience and our idea of the product. Let’s summarize in this short sentence all our thoughts of all time:

“… with a little more I really have a lot more!”

Let’s start the comparison by laying the product bare

ABACO can be made in both removable fabric and semi-removable leather.

Feet, armrests, seat cushions and back cushions are completely removable. This absolutely facilitates ordinary cleaning operations and complete washing of the covering.

I PIEDI

The feet are not visible but there are! They are made of PVC, are non-slip and have a shape that allows maximum tranquility of use, even with particularly delicate wooden floors.

In the image to the side, we see the fixing system (in section).

Comparison:

It is a foot commonly used by all companies. No particular added value compared to the competition regarding this type of foot.

THE STRUCTURE AND THE SPRINGING

We have already talked about the frame in the previous article dedicated to the Infinito model. Today we just want to remind you that the supporting frame must be made of wood, to guarantee support and to guarantee the fixing of the elastic bands that make up the spring system.

We want to dedicate a few lines to this topic (semi-unknown to most users).

The elastic band is commonly called “belt” and makes up the spring system that underlies the seat.

The belt is with the padding, a fundamental part of a sofa, because it determines its comfort and often determines its duration.

Some models do not have belts but the seat cushion rests directly on the plywood floor. Our Life and Loft models reflect this type of product.

Generally the sofas have a belt with vertical and horizontal bands, to balance the elasticity and distribute the weight loads.

This spring system, elaborated during the study phase of the model, is also determined on the basis of the choice of polyurethane for the seat. The softness, elasticity and bearing capacity of the seat cushion must be evaluated in order to combine adequate springing. the final result is determined by the company, based on its sensitivity and its idea of the product.

Without going into detail (the values expressed are difficult to interpret), we only indicate that there are several elastic bands. on the market.

They have different costs, have different behaviors based on the elastic component (usually the amount of caoutchouc) and the width.

Now let’s illustrate a very important moment in the creation of the spring system: the determination of the “draught”. By clicking on the next video you will see the operation necessary to determine the belt tension.

This video will allow everyone to better understand the close relationship between:

tension -> elasticity -> lift.

(I hope you will forgive the “do it yourself” video that we made in production. Even if a little exasperated, it allows you to understand the importance of spring calibration).

Tension – Elasticity – Lift must be well proportioned

Although many artisan realities carry out this operation really by hand (as in the video), without a real measurement of the tension, within our company this operation is done by a machine, with which the tension of the belt is programmed, as required by the model sheet.

This allows for guaranteed product uniformity over time.

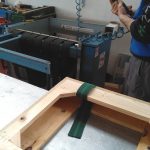

To the side you can see a single strapping station.

Now it’s easy to understand that the springing can be adjusted, but the biggest problem is that the springing must perfectly integrate with the softness, elasticity and lift of the padding!! This is the only way to get perfect comfort.

Only the sum of the 2 components determines the ideal comfort of every sofa.

To make a comparison, we can define the combined seat / padding spring system in sofas, in the same way as the combined base / mattress for beds.

We can guarantee that nothing is left to chance.

Comparison

You may also accept some chipboard parts if placed in unimportant areas.

Let’s make sure though that the heavily stressed parts like

- foot support and

- the fastening part of the elastic straps (those that guarantee the springing)

are not chipboard but WOOD or MULTI-LAYER.

The value of an ABACO structure compared to an economic structure is 5 times higher.

THE PADDING

The information on padding is very technical and not everyone has the interest and knowledge to understand the meaning of certain terms, but above all to understand the values they represent.

The term that is normally known is that of density, but although it certainly has a meaning, it is a partial and non-exhaustive value.

Just for information we inform you that there are many other fundamental parameters:

- The resistance to compression

- Elasticity

- The lift

- … and many other values that we will not go into further.

Padding supports the body and is essential for comfort.

Differentiated-density padding finished with pre-lining in cotton.

Differentiated-density padding finished with pre-lining in cotton.

A decidedly different way to build a seat (compared to what is commonly found on the market) is to:

- Use a basic polyurethane with a good density and with important values of lift and resistance to compression.

- Use a second polyurethane in the upper parts, soft, elastic, welcoming, which has the purpose of not excessively compressing the body when seated.

- Coat everything with acrylic wadding to give the seat the desired shape.

- Finally, cover the whole cushion with a cotton cover finished with an overlock.

This is a construction system of a superior range padding and it is precisely the case of the seat padding of the Abaco model.

We also remind you that the wider the padding (80-90-100-120 cm.) the better they must be performing!

The backrest padding is also of a higher category. They have been made in a down blend with insulation chambers. They represent the best combination of the softness of feathers and the practicality of polyurethane. They adapt to the body, change in shape, allow correct back support, therefore an important ergonomic function! But they come back in shape with great ease. And not only.

They enhance the design, removing the excessive formal rigidity typical of expanded polyurethane. The lived-in effect, informal, not excessive, always has its charm.

Comparison

The value of an Abaco padding compared to a cheap padding is about 5 times higher.

THE COVERING

ALL THE ELEMENTS ARE FULLY UNCOVERABLE

This fact is also common to many other products on the market, but we would like to point out that “undressing” the sofa is a fairly simple operation, but “upholstering” the sofa is a completely different matter.

The ABACO construction system has been designed precisely for this purpose: to facilitate the operations of

RE-COVER!

Comparison

The working time required to make the Abaco cover more removable than for a cheaper type is over 20%.

Of course, if someone overlooks all the information we have provided and chooses ABACO (or INFINITO) simply because it is

COMFORTABLE and it’s really A BEAUTIFUL SOFA!

we confirm that he is absolutely right!